Search Product

Search here for what you are looking for:

Search here for what you are looking for:

Stainless steel mesh is a versatile material that finds applications in various industries due to its heat resistance, acid resistance, corrosion resistance, and wear resistance. The different varieties of stainless steel mesh offer unique features and are used for specific purposes. This article provides an overview of the classification of stainless steel mesh by variety, highlighting their characteristics and applications in industries such as mining, chemical, food, petroleum, and medicine.

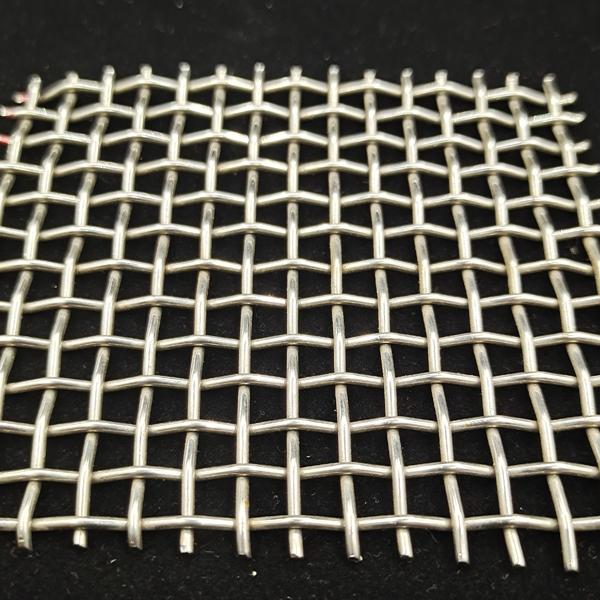

Stainless Steel Plain Mesh:

Characteristics: This type of mesh features a simple plain weave pattern, providing a uniform structure. It is known for its durability and versatility.

Applications: Widely used for gas and liquid filtration, sieving, and separation processes in industries such as mining, chemical, food, and pharmaceutical.

Stainless Steel Diagonal Mesh:

Characteristics: Diagonal mesh is woven with a diagonal pattern, resulting in increased strength and stability. It offers excellent filtration capabilities and durability.

Applications: Suitable for applications requiring strong and reliable filtration, such as chemical processing, oil refineries, and wastewater treatment plants.

Stainless Steel Bamboo Patterned Mesh:

Characteristics: Bamboo patterned mesh is characterized by its unique bamboo-like design. It combines aesthetic appeal with functionality, offering good filtration and screening properties.

Applications: Used in architectural projects, interior design, decorative panels, and artistic applications where both functionality and visual appeal are desired.

Five Stainless Steel Mesh:

Characteristics: Five stainless steel mesh, also known as twill weave mesh, has a distinct pattern that offers higher strength and finer filtration compared to plain weave mesh.

Applications: Widely used in fine filtration applications, such as water treatment, food processing, and pharmaceutical industries.

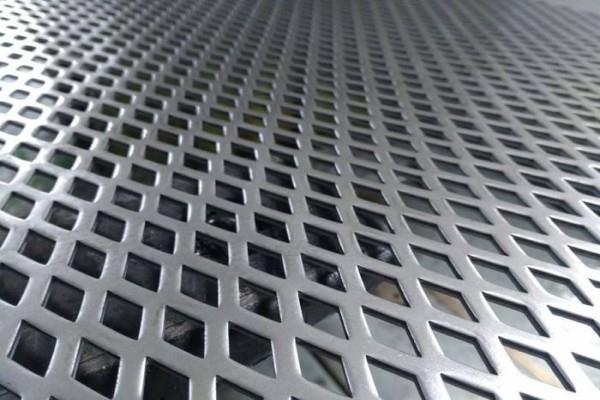

Stainless Steel Punching Mesh:

Characteristics: Punching mesh is produced by mechanically punching holes into stainless steel sheets, resulting in various hole patterns and sizes. It offers excellent ventilation and light transmission.

Applications: Used for architectural purposes, sound insulation, building facades, protective enclosures, and automotive components.

Stainless Steel Embossed Mesh:

Characteristics: Embossed mesh features raised patterns or designs on the surface, enhancing its aesthetic appeal. It offers good ventilation and light transmission.

Applications: Commonly used in decorative applications, partitions, staircases, and furniture design.

Stainless Steel Hook Mesh:

Characteristics: Hook mesh is designed with interlocking hooks, providing enhanced strength and stability. It offers excellent load-bearing capabilities.

Applications: Suitable for heavy-duty applications such as safety barriers, machine guards, and storage enclosures.

Stainless Steel Plate Mesh:

Characteristics: Plate mesh is made from stainless steel plates that are welded together, creating a robust and rigid structure. It offers high strength and durability.

Applications: Used in industrial applications requiring heavy loads, such as platforms, walkways, and industrial flooring.

Stainless Steel Welded Mesh:

Characteristics: Welded mesh is formed by welding stainless steel wires at the intersections, resulting in a strong and rigid mesh structure. It offers excellent strength and corrosion resistance.

Applications: Widely used in construction, fencing, animal enclosures, and reinforcement applications.

Stainless Steel Hexagonal Mesh:

Characteristics: Hexagonal mesh, also known as chicken wire, features a hexagonal pattern formed by weaving stainless steel wires. It offers good flexibility and corrosion resistance.

Applications: Used in agriculture, animal enclosures, garden fencing, and soil erosion control.

Stainless Steel Mat Mesh:

Characteristics: Mat mesh consists of stainless steel wires intertwined to form a dense and durable mesh. It offers excellent stability and load-bearing capabilities.

Applications: Suitable for industrial applications such as conveyor belts, machine guards, and filtration systems.

Stainless Steel Barbecue Net:

Characteristics: Barbecue nets are composed of stainless steel wires woven together, providing a stable and heat-resistant surface for grilling.

Applications: Used in outdoor cooking, barbecues, and food processing industries.

Stainless Steel Mine Screen Mesh:

Characteristics: Mine screen mesh is designed with high tensile strength and abrasion resistance to withstand harsh mining environments. It offers efficient particle separation and durability.

Applications: Primarily used in the mining industry for screening and classifying ores, coal, and other materials.

Stainless Steel Turtle Shell Mesh:

Characteristics: Turtle shell mesh features a unique pattern resembling a turtle's shell. It offers high strength, stability, and aesthetic appeal.

Applications: Used in architectural projects, interior design, decorative panels, and artistic applications where a visually striking pattern is desired.

The wide range of stainless steel mesh varieties, including plain mesh, diagonal mesh, bamboo patterned mesh, and many others, cater to diverse industrial applications. With their heat resistance, acid resistance, corrosion resistance, and wear resistance properties, stainless steel meshes are extensively used for gas and liquid filtration, sieving, and separation in industries such as mining, chemical, food, petroleum, and medicine. Understanding the characteristics and applications of various stainless steel mesh varieties allows industries to choose the most suitable option for their specific needs

Basic parameters of stainless steel mesh - wire diameter, aperture, weight:

Weaving method | Mesh count | Wire diameter(mm) | Mesh(mm) | Weight (kg/square meter) |

Plain weave | 1Mesh | 2mm | 23.4 | 2.0 |

Plain weave | 2Mesh | 1.5mm | 11.2 | 2.25 |

Plain weave | 3Mesh | 1.0mm | 7.466 | 1.5 |

Plain weave | 4Mesh | 0.9mm | 5.45 | 1.62 |

Plain weave | 5Mesh | 0.8mm | 4.28 | 1.6 |

Plain weave | 6Mesh | 0.7mm | 3.53 | 1.47 |

Plain weave | 7Mesh | 0.6mm | 3.02 | 1.26 |

Plain weave | 8Mesh | 0.5mm | 2.675 | 1.0 |

Plain weave | 9Mesh | 0.5mm | 2.322 | 1.125 |

Plain weave | 10Mesh | 0.8mm | 1.74 | 3.2 |

Plain weave | 11Mesh | 0.7mm | 1.609 | 2.695 |

Plain weave | 12Mesh | 0.6mm | 1.516 | 2.16 |

Plain weave | 13Mesh | 0.5mm | 1.453 | 1.625 |

Plain weave | 14Mesh | 0.4mm | 1.414 | 1.12 |

Plain weave | 15Mesh | 0.4mm | 1.293 | 1.2 |

Plain weave | 16Mesh | 0.35mm | 1.237 | 0.98 |

Plain weave | 17Mesh | 0.35mm | 1.144 | 1.041 |

Plain weave | 18Mesh | 0.35mm | 1.061 | 1.10 |

Plain weave | 19Mesh | 0.35mm | 0.986 | 1.16 |

Plain weave | 20Mesh | 0.4mm | 0.97 | 0.97 |

Plain weave | 21Mesh | 0.3mm | 0.909 | 0.945 |

Plain weave | 22Mesh | 0.3mm | 0.854 | 0.99 |

Plain weave | 23Mesh | 0.25mm | 0.854 | 0.718 |

Plain weave | 24Mesh | 0.25mm | 0.858 | 0.48 |

Plain weave | 25Mesh | 0.2mm | 0.816 | 0.50 |

Plain weave | 26Mesh | 0.2mm | 0.776 | 0.52 |

Plain weave | 27Mesh | 0.2mm | 0.740 | 0.54 |

Plain weave | 28Mesh | 0.3mm | 0.607 | 1.26 |

Plain weave | 29Mesh | 0.3mm | 0.575 | 1.30 |

Plain weave | 30Mesh | 0.3mm | 0.546 | 1.35 |

Plain weave | 40Mesh | 0.25mm | 0.385 | 1.25 |

Plain weave | 50Mesh | 0.2mm | 0.308 | 1.0 |

Plain weave | 60Mesh | 0.15mm | 0.273 | 0.675 |

Plain weave | 70Mesh | 0.14mm | 0.222 | 0.686 |

Plain weave | 80Mesh | 0.12mm | 0.197 | 0.576 |

Plain weave | 90Mesh | 0.11mm | 0.172 | 0.544 |

Plain weave | 100Mesh | 0.10mm | 0.154 | 0.50 |

Plain weave | 120Mesh | 0.08mm | 0.131 | 0.384 |

Plain weave | 150Mesh | 0.07mm | 0.099 | 0.367 |

Plain weave | 380Mesh | 0.02mm | 0.046 | 0.076 |

Plain weave | 400Mesh | 0.018mm | 0.0455 | 0.0648 |