Search Product

Search here for what you are looking for:

Search here for what you are looking for:

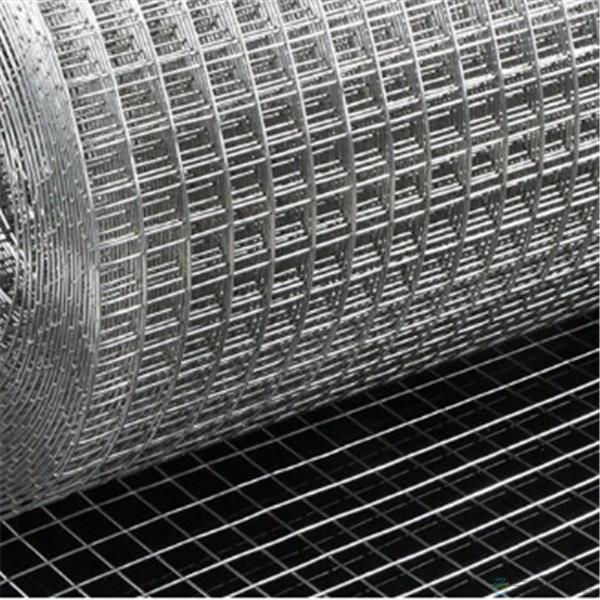

Stainless steel wire mesh is a versatile material that is widely used in various industries for its strength, durability, and corrosion resistance. One of the key factors that determine the characteristics and applications of stainless steel wire mesh is the weaving method used during its production. In this article, we will explore the different weaving methods commonly employed to create stainless steel wire mesh.

Plain Weave:

Plain weave is a fundamental weaving method where each warp thread crosses over and under each weft thread, forming a 90-degree angle. This method creates a simple and balanced mesh structure. In plain weave, both the warp and weft threads have the same diameter, resulting in equal-sized openings throughout the mesh. Plain weave stainless steel wire mesh is commonly used in general filtration, sieving, and architectural applications.

Twill Weave:

Twill weave is a weaving method where each warp thread crosses over and under multiple weft threads. The most common twill weave pattern used in stainless steel wire mesh is the 2/2 twill, where each warp thread goes over two weft threads and under two weft threads consecutively. This weaving technique creates diagonal lines or patterns on the mesh surface. Twill weave stainless steel wire mesh offers increased strength and stability compared to plain weave, making it suitable for applications that require robust filtration, separation, and reinforcement.

Dense Weave:

Dense weave, also known as mat mesh, is a type of stainless steel wire mesh characterized by varying warp and weft diameters and mesh sizes. In dense weave, the warp threads are sparser, while the weft threads are denser, resulting in a coarse warp and fine weft structure. This type of mesh is further divided into flat weave mesh and diagonal weave mesh.

Mat Shaped Mesh Twill Weaving:

Mat shaped mesh twill weaving is a weaving method where each diameter wire crosses and passes up and down every two weft wires, while each weft wire crosses and passes up and down every two diameter wires. This weaving technique creates a sturdy and durable mesh with enhanced filtration capabilities. It is commonly used in applications that require precise filtration at the micro-level.

Double Silk Dutch Weaving:

Double silk Dutch weaving is similar to twill Dutch weaving and involves tightly intertwining two weft threads with the warp threads. This type of weaving creates a mesh with excellent filtration properties, particularly for micrometer-level filtering applications.

Five-Fold Weaving:

Five-fold weaving utilizes multiple separate threads for both the warp and weft instead of single threads. This technique provides a stronger and more robust foundation compared to traditional twill weaving. Five-fold weaving is employed in applications that require enhanced strength, stability, and resistance to mechanical stress.

Stainless steel wire mesh produced using these various weaving methods offers a wide range of applications across industries such as filtration, separation, protection, and reinforcement. Whether it's plain weave for general purposes, twill weave for added strength, or dense weave for precise filtration, selecting the appropriate weaving method is crucial to meet the specific requirements of each application.

In conclusion, the weaving method used in the production of stainless steel wire mesh greatly influences its characteristics and performance. Each weaving technique offers unique advantages, allowing stainless steel wire mesh to fulfill diverse industrial needs. By understanding the different weaving methods and their applications, industries can make informed choices when selecting stainless steel wire mesh for their specific requirements.