Search Product

Search here for what you are looking for:

Search here for what you are looking for:

Have you ever wondered why stainless steel screens sometimes turn black during use? The answer lies in the composition of the raw materials. Let's delve into the analysis below.

One of the key components of stainless steel is a combination of iron, nickel, and chromium. These three metal alloys play a significant role in determining the production ratios and performance of stainless steel products, resulting in variations in appearance. Higher chromium content leads to a brighter color of the stainless steel wire, while higher nickel content contributes to a darker color. If the ratio of iron and nickel remains constant and the chromium content increases, the stainless steel wire can gradually turn black. This analysis primarily focuses on the appearance of the product during its early development stages.

In certain cases, blackening of stainless steel screens in toilets is caused by oxidation. When heated, the iron within the stainless steel undergoes rapid changes and gasification, without displaying any signs of rust.

Another scenario occurs during the production process, where insufficient lubrication of the drawing machine leads to excessive friction and overheating of the stainless steel wire's surface. This results in the precipitation of metal elements within the wire, causing alloy analysis and surface blackening.

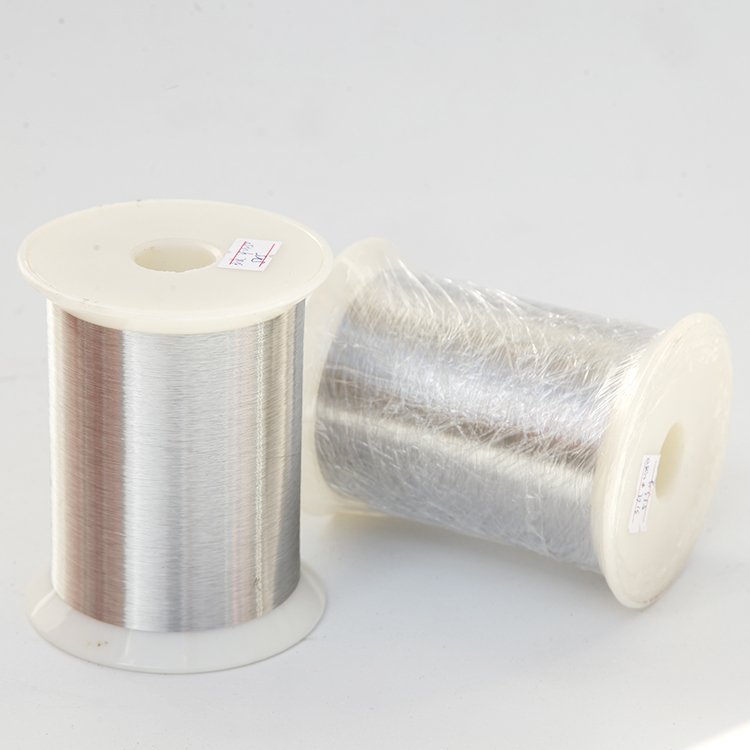

Stainless steel mesh comes in various types, such as stainless steel square eye mesh, stainless steel mesh (pad) with ultra-wide dimensions (ranging from 1.2 to 3.5 meters in width and 5 to 8 meters in length), large wire mesh, stainless steel mesh lunch box mesh with custom specifications, and stainless steel wire mesh. These products are manufactured through the advanced processing of high-quality stainless steel wire ropes, including 302, 304, 304L, 316, and 316L.

The weaving methods used for stainless steel wire mesh include plain weave, twill weave, and dense weave. Thanks to the inherent characteristics of stainless steel, the processed wire mesh exhibits exceptional wear resistance, extended service life, precise mesh openings, uniform structure, easy handling, consistent mesh thickness, electrostatic resistance, acid and alkali resistance, corrosion resistance, temperature resistance, and excellent durability. As a result, stainless steel wire mesh finds widespread applications in industries such as machinery, coal mining, petroleum, chemicals, food processing, and pharmaceuticals.

In conclusion, understanding the factors influencing the occasional blackening of stainless steel screens involves analyzing the composition of raw materials and considering production-related elements. The versatility and exceptional properties of stainless steel wire mesh make it a preferred choice across various industries.