Search Product

Search here for what you are looking for:

Search here for what you are looking for:

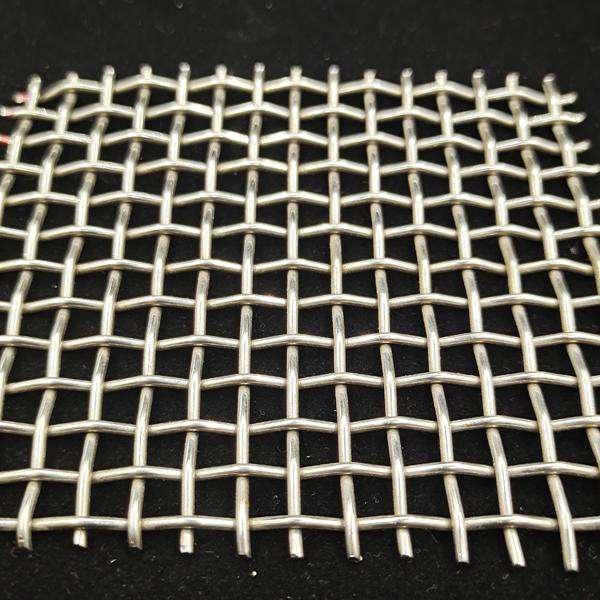

Stainless steel wire mesh is a versatile material that finds extensive use in various industries. Understanding its specifications is crucial for selecting the right mesh for specific applications. This article provides a detailed overview of the specifications of stainless steel wire mesh, including mesh size, material, width, length, wire diameter, and weaving method. Additionally, it explores the advantages and applications of stainless steel wire mesh in different industries.

Mesh Size:

The mesh size of stainless steel wire mesh refers to the number of holes per inch. A higher mesh size indicates smaller holes. Common mesh sizes include 4, 10, 20, 30, 40, 50, 60, 80, 100, 120, 150, 200, 300, 325, and 400. The choice of mesh size depends on the intended application and the desired level of filtration or separation.

Material:

Stainless steel wire mesh is available in different materials, including SUS201, 302, 304, 304L, 316, and 316L. The choice of material depends on the specific requirements of the application, such as corrosion resistance, temperature resistance, and chemical compatibility.

Weaving Method:

Stainless steel wire mesh is commonly woven using several methods, including plain weave, twill weave, dense weave, and mat weave. The weaving method determines the density of the mesh, the uniformity of wire diameters, and the overall structure of the mesh. Each weaving method offers different characteristics and is chosen based on the desired functionality of the mesh.

Advantages of Stainless Steel Wire Mesh:

Stainless steel wire mesh offers numerous advantages, including:

High wear resistance and long service life

Accurate mesh size and uniform structure

No curling and easy to use

Uniform screen thickness and anti-static properties

Excellent acid and alkali resistance, corrosion resistance, and temperature resistance

Applications of Stainless Steel Wire Mesh:

Stainless steel wire mesh finds diverse applications in various industries, including:

Petrochemical Industry: Used as mud screens in the petroleum industry for filtration and separation purposes.

Chemical Industry: Employed as screen filters in the chemical fiber industry.

Electroplating Industry: Used for product classification and filtration.

Mining Industry: Utilized for screening and filtration in mining operations.

Food and Pharmaceutical Industry: Applied for sieving, filtration, and separation processes.

Machinery Manufacturing: Used in machinery parts, screens, and filters.

Stainless steel wire mesh is a highly versatile material with a wide range of specifications and applications. Understanding the mesh size, material, weaving method, and advantages is crucial for selecting the appropriate wire mesh for specific industrial requirements. Whether it's for filtration, separation, screening, or protection, stainless steel wire mesh offers durability, reliability, and superior performance in various industries.