Search Product

Search here for what you are looking for:

Search here for what you are looking for:

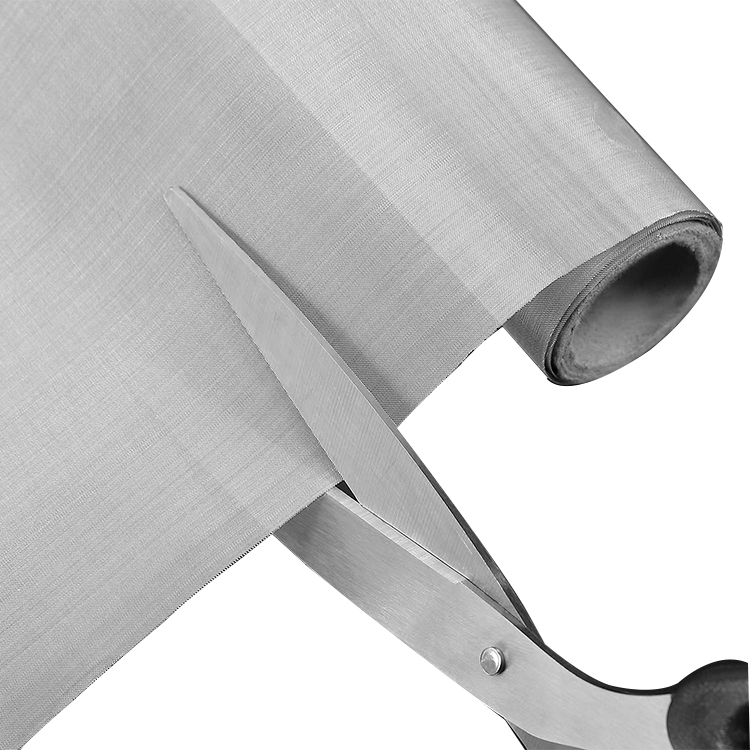

Stainless steel mesh is widely used in industrial applications due to its durability, versatility, and corrosion resistance. To ensure optimal performance and longevity, proper maintenance and considerations are essential. This article explores the maintenance requirements and important considerations for stainless steel mesh in industrial settings.

Regular Cleaning and Inspection:

Regular cleaning is crucial to maintain the performance of stainless steel mesh. Dust, debris, and contaminants can accumulate on the surface over time, compromising its effectiveness. Cleaning the mesh with water and mild detergent, followed by thorough rinsing, helps remove dirt and maintain its functionality. Additionally, periodic inspections should be conducted to identify any signs of wear, corrosion, or damage that may require repair or replacement.

Protection Against Corrosion:

Although stainless steel mesh is highly resistant to corrosion, certain industrial environments may pose a risk. Exposure to chemicals, high humidity, or saltwater can increase the likelihood of corrosion. Applying a protective coating or using a higher grade of stainless steel, such as 316 or 904L, can enhance corrosion resistance and prolong the mesh's lifespan in challenging conditions.

Proper Handling and Installation:

During handling and installation, it is crucial to avoid causing damage to the mesh. Sharp or abrasive objects should be kept away from the mesh to prevent scratches or punctures. Care should be taken to ensure proper tensioning and securing of the mesh to prevent sagging or loosening, which can affect its performance.

Consideration of Mesh Size and Specifications:

Choosing the appropriate mesh size and specifications is vital for successful industrial applications. Consider factors such as the desired level of filtration, flow rates, and material compatibility when selecting the mesh size and specifications. Consultation with experts or suppliers can help determine the most suitable mesh for specific industry requirements.

Temperature and Pressure Considerations:

Industrial processes often involve high temperatures and pressures. It is crucial to select stainless steel mesh that can withstand these conditions without deformation or loss of structural integrity. Considering the operating temperature and pressure range is essential to ensure the longevity and reliability of the mesh in industrial applications.

Regular Maintenance and Replacement:

While stainless steel mesh is known for its durability, it is important to monitor its performance over time. Regular maintenance and preventive measures, such as cleaning, inspection, and corrosion protection, can help identify any issues early on. If signs of significant wear or damage are detected, timely replacement of the mesh is necessary to maintain optimal performance and safety.

Proper maintenance and considerations are vital for maximizing the performance and lifespan of stainless steel mesh in industrial applications. Regular cleaning, inspection, and protection against corrosion are essential maintenance practices. Additionally, selecting the appropriate mesh size and specifications, handling and installing the mesh properly, and considering temperature and pressure requirements are crucial for successful industrial applications. By following these guidelines, industries can ensure the longevity and reliability of stainless steel mesh in their operations, enabling efficient and effective processes.