Search Product

Search here for what you are looking for:

Search here for what you are looking for:

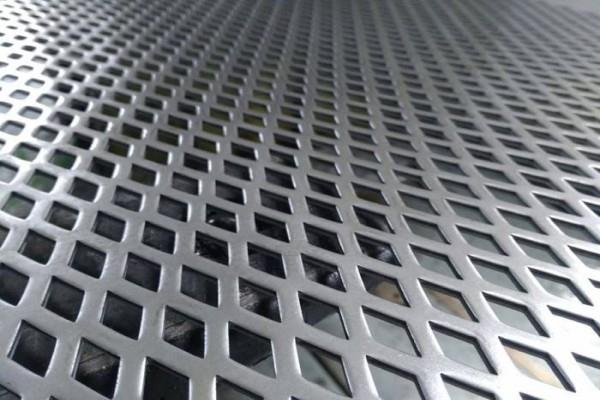

Stainless steel filter screens are essential components used in various industries for screening and filtration purposes. The specifications of these screens, such as mesh size, material, wire diameter, and length, determine their filtering accuracy and suitability for different applications. In this article, we will delve into the characteristics and applications of three commonly used stainless steel filter screens: 40 mesh, 60 mesh, and 80 mesh.

40 Mesh Stainless Steel Filter Screen:

The 40 mesh stainless steel filter screen is typically 1 meter wide and 30 meters long, made of 304 material. It has a wire diameter of 0.21mm and a mesh size of 0.42mm. With 40 mesh holes per inch, it offers the following characteristics:

Filtering Accuracy and Corrosion Resistance: The 40 mesh stainless steel screen features a uniform mesh that provides excellent filtering accuracy. It exhibits remarkable corrosion resistance, making it suitable for use in acidic and alkaline environments.

Convenient Maintenance: The screen has a high level of smoothness and does not require surface treatment, ensuring convenient and simple maintenance.

High Temperature Resistance: Made of 304 stainless steel, the 40 mesh screen can withstand temperatures up to 400 degrees Celsius, making it suitable for applications involving high-temperature environments.

Durability and Strength: The screen possesses high strength, tensile strength, toughness, and wear resistance, ensuring its durability and long-lasting performance.

Applications of 40 Mesh Stainless Steel Filter Screen:

Petrochemical Industry: The 40 mesh screen is used as mud screens in the petroleum industry.

Chemical Fiber Industry: It serves as screen filters in the chemical fiber industry.

Electroplating Industry: The screen finds application as acid washing screens in the electroplating industry.

Mining, Food, Medicine, Machinery Manufacturing, Aerospace, and Transportation Industries: The 40 mesh screen is utilized in various industries for screening, filtration, and separation purposes, catering to diverse needs.

60 Mesh Stainless Steel Filter Screen:

The 60 mesh stainless steel filter screen shares similar specifications, including a width of 1 meter, a length of 30 meters, and 304 material. However, it has a smaller wire diameter of 0.15mm and mesh holes of 0.27mm. With 60 mesh holes per inch, it offers the following characteristics:

Filtering Accuracy and Corrosion Resistance: The 60 mesh screen provides precise filtering accuracy and exhibits excellent corrosion resistance properties.

Easy Maintenance: Similar to the 40 mesh screen, the 60 mesh screen offers high smoothness and requires no surface treatment for convenient maintenance.

High Temperature Resistance: Withstanding temperatures up to 600 degrees Celsius, the 60 mesh screen is suitable for applications involving high-temperature environments.

Durability and Strength: The screen is known for its high strength, tensile strength, toughness, and wear resistance, ensuring its longevity and reliability.

Applications of 60 Mesh Stainless Steel Filter Screen:

The applications of the 60 mesh stainless steel filter screen overlap with those of the 40 mesh screen, finding utility in the petrochemical, chemical fiber, electroplating, mining, food, medicine, machinery manufacturing, aerospace, and transportation industries.

80 Mesh Stainless Steel Filter Screen:

The 80 mesh stainless steel filter screen is also 1 meter wide and 30 meters long, made of 304 material. It features a wire diameter of 0.12mm and mesh holes of 0.2mm, with 80 mesh holes per inch. It offers the following characteristics:

Precise Filtering and Corrosion Resistance: The 80 mesh screen provides precise filtering capabilities and exhibits excellent corrosion resistance.

Convenient Maintenance: Similar to the other screens, the 80 mesh screen has high smoothness and requires no surface treatment for easy maintenance.

High Temperature Resistance: With a remarkable capacity to withstand temperatures up to 800 degrees Celsius, the 80 mesh screen is suitable for high-temperature environments.

Durability and Strength: The screen possesses high strength, tensile strength, toughness, and wear resistance, ensuring its durability and long-lasting performance.

Applications of 80 Mesh Stainless Steel Filter Screen:

The applications of the 80 mesh stainless steel filter screen mirror those of the 40 mesh and 60 mesh screens, finding utility in various industries for screening, filtration, separation, and protection purposes.

Stainless steel filter screens, including the 40 mesh, 60 mesh, and 80 mesh variants, play a crucial role in screening and filtration applications across diverse industries. With their uniform mesh, corrosion resistance, high temperature resistance, durability, and strength, these screens provide effective filtering and long-lasting performance. From the petrochemical and chemical industries to mining, food, medicine, machinery manufacturing, aerospace, and transportation sectors, stainless steel filter screens find versatile applications, contributing toenhanced productivity, efficiency, and safety in industrial processes. Their wide-ranging uses in screening sand particles, filtering liquids and gases, and even replacing traditional materials in construction highlight their versatility and adaptability.

As technology and industrial processes continue to evolve, stainless steel filter screens will remain essential components in ensuring optimal performance and quality control. With their reliable characteristics and diverse applications, the 40 mesh, 60 mesh, and 80 mesh stainless steel filter screens continue to contribute to various industries, supporting advancements and innovation.

In conclusion, the 40 mesh, 60 mesh, and 80 mesh stainless steel filter screens offer uniform mesh, corrosion resistance, high temperature resistance, durability, and strength. These characteristics make them indispensable in screening, filtration, and separation processes across industries such as petrochemicals, chemical fiber, electroplating, mining, food, medicine, machinery manufacturing, aerospace, and transportation. With their reliability and versatility, these filter screens continue to play a vital role in enhancing industrial processes and ensuring optimal performance.