Search Product

Search here for what you are looking for:

Search here for what you are looking for:

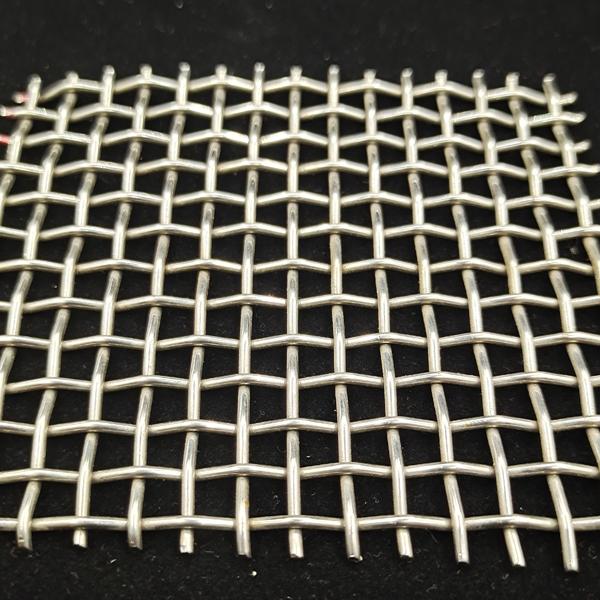

Stainless steel mesh is a versatile material with unique properties that make it suitable for a wide range of applications. The weaving methods used in its production, such as plain weave, diagonal weave, and dense weave, contribute to its durability, uniform structure, and ease of use. With inherent characteristics like wear resistance, long service life, and resistance to corrosion, acid, alkali, and high temperatures, stainless steel mesh has found extensive use in industries such as coal mining, petroleum, chemical, food, and medicine. This article explores different types of stainless steel mesh and their specific applications.

201 Stainless Steel Mesh (Ni0):

Performance: This type of stainless steel mesh exhibits acid and alkali resistance, high density, and excellent polishing characteristics without bubbles.

Usage: Widely employed in industries such as mining, chemicals, food, petroleum, and medicine for gas and liquid filtration and mass separation.

Features: Known for its uniform mesh structure, good filtering accuracy, and sturdy and durable construction.

Mesh size: Available in a range from 1 to 150 mesh.

304 Stainless Steel Mesh (Ni8):

Performance: Offers excellent corrosion resistance, including resistance to intergranular corrosion. It withstands nitric acid with concentrations below 65% boiling temperature and demonstrates good resistance to alkaline and most organic and inorganic acids.

Usage: Primarily used for screening and filtration in acidic and alkaline environments. Also applied in mining, chemical, food, and pharmaceutical industries.

Features: Provides good filtration accuracy, corrosion resistance, and durability. It exhibits resistance to acid, alkali, wear, and high temperatures up to 800 degrees Celsius.

Mesh size: Available in a range from 0.5 to 325 mesh.

316 Stainless Steel Mesh:

Features: Exhibits superior corrosion resistance compared to other nickel stainless steels, particularly in saltwater, sulfur water, and corrosive industrial atmospheres. It is highly resistant to corrosion in the production process of pulp and paper.

Performance: Offers high wear resistance, acid and alkali resistance, high temperature resistance up to 1000 degrees Celsius, and static electricity prevention.

Usage: Well-suited for screening and filtration in acidic and alkaline conditions. Widely used in industries such as petroleum, chemical fibers, electroplating, and acid washing.

Mesh size: Available in a range from 1 to 2300 mesh.

310 Stainless Steel Mesh:

Features: Utilizes nickel-chromium and nickel-chromium-iron electric heating alloy wire, providing excellent high-temperature resistance, high strength, and non-softening properties. The Cr20Ni80 alloy stands out for its exceptional characteristics and is employed in high-quality electric heating elements.

Performance: Exhibits high temperature resistance of 1000-1200 degrees Celsius, making it suitable for applications in boilers, steam turbines, power plants, annealing furnaces, industrial furnaces, and the aviation and petrochemical industries.

Usage: Widely used in fields that require high-temperature insulation. Common applications include boilers, steam turbines, power plants, annealing furnaces, food barbecues, industrial furnaces, aviation, and petrochemical industries.

Mesh size: Customized to meet specific requirements, including material, wire diameter, mesh hole, length, width, and whether the mesh structure is woven or welded.

Stainless steel mesh, with its diverse weaving methods and inherent properties, plays a crucial role in various industries. The different types of stainless steel mesh, such as 201, 2304, 316, and 310 variations, offer specific characteristics suited to different applications. From gas and liquid filtration to screening and separation, stainless steel mesh provides durability, corrosion resistance, high temperature resistance, and wear resistance. Its widespread use in industries like mining, chemicals, food, petroleum, and medicine highlights its versatility and reliability. As industries continue to evolve, stainless steel mesh will remain an essential component for ensuring efficient and effective processes across a range of applications.